ATE PLAST

FLEXO PRINT

Leading manufacturer of flexible polymer films and packaging for the industry. The company is oriented towards innovations and leading trends and solutions in the packaging industry. The capacity of the plant for flexible printed and laminated packaging is 2000 tons / year.

01

Our kwoledge and know-how of polymer film production, gives the benefir to offer the right film with highest packaging output for our customers.

02

We are specialized in finding the right packaging solution: the most appropriate flexible packaging for your machine, its speed and barrier characteristics of the film according to the final application and product packed.

03

ATE PLAST works 24/7 with continuous production, which leads to shorter delivery times and flexibility.

04

The wide production range allows the supply of foils and packaging materials for the food, hygiene and chemical industries.

05

Different printing effects: soft touch, matt lacquer, glossy lacquer, paper touch.

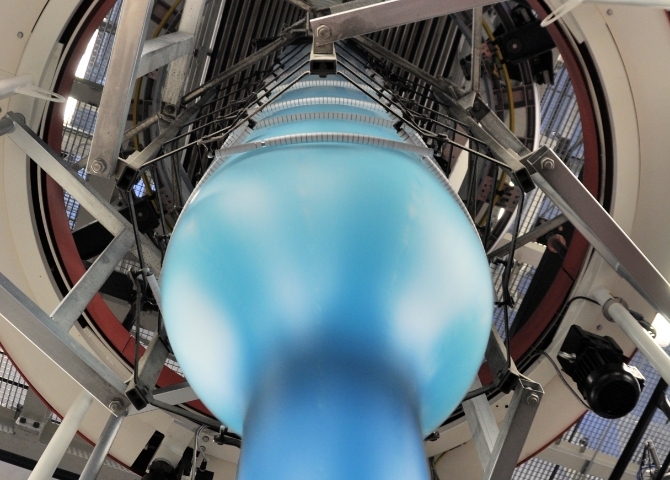

Monolayer and multilayer extrusion. Extrusion of specialized and barrier films – for printing and laminating, collation-shrink films, films for packaging vertical (VFFS) and horizontal (flow pack) machines.

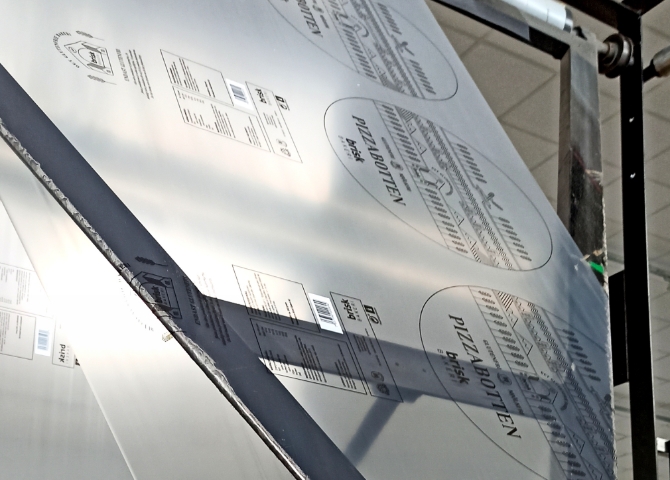

Flexo printing is one of the most widely used printing methods, characterized by quality, versatility and productivity. We offers flexo printing up to 8 + 1 colors for excellent product presentation.

The company can meet a wide range of requirements in terms of transparency, strength, elasticity, sealing and barrier properties. ATE PLAST offers also high barrier packaging films, laminated with aluminum foil.

Our foils are also available in the form of pre-made bags, covers, sheets and wicket bags. They are excellent protection for your products. We offer them loose or on a roll with a tear-off perforation.